Current RnD Projects

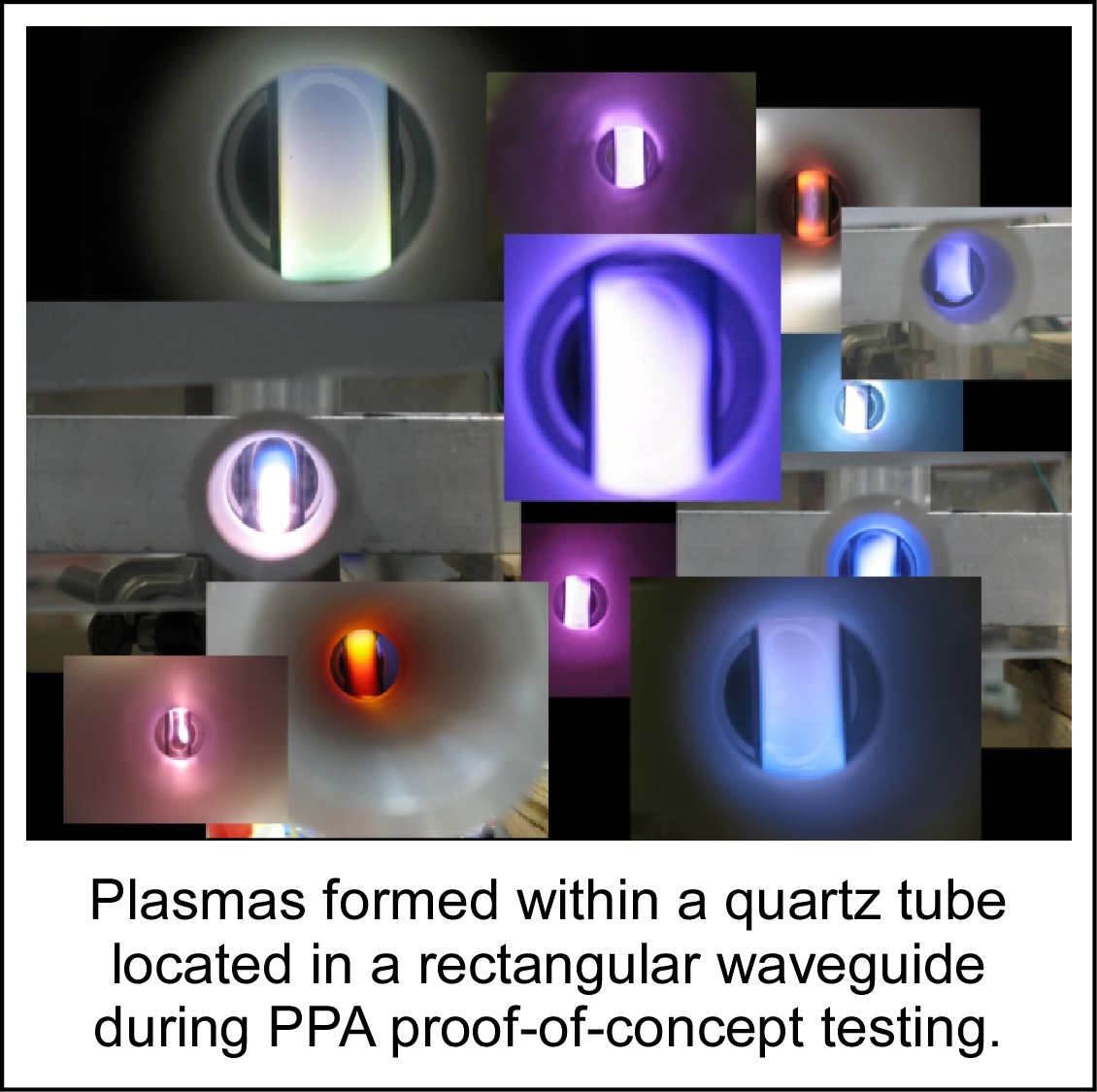

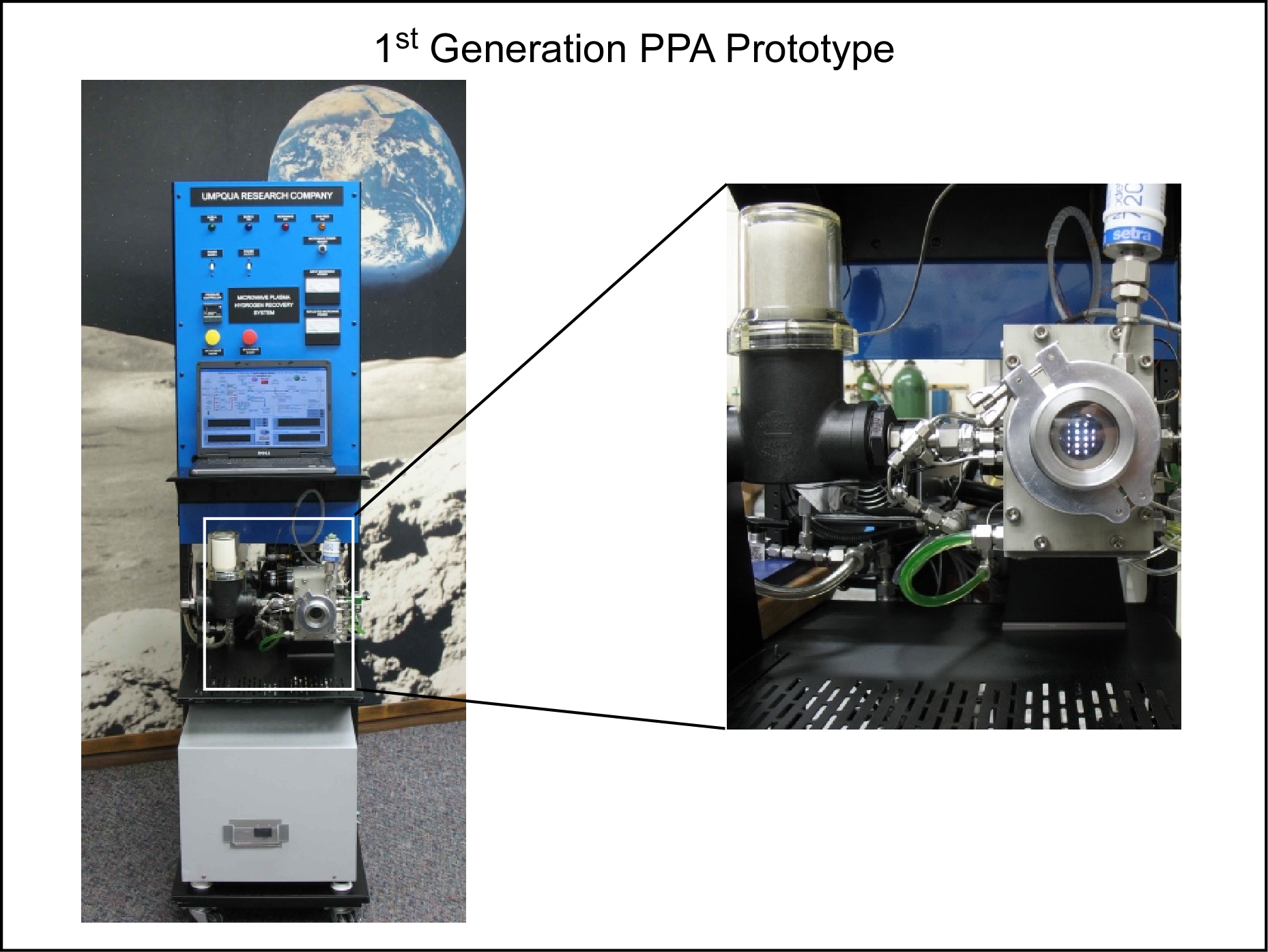

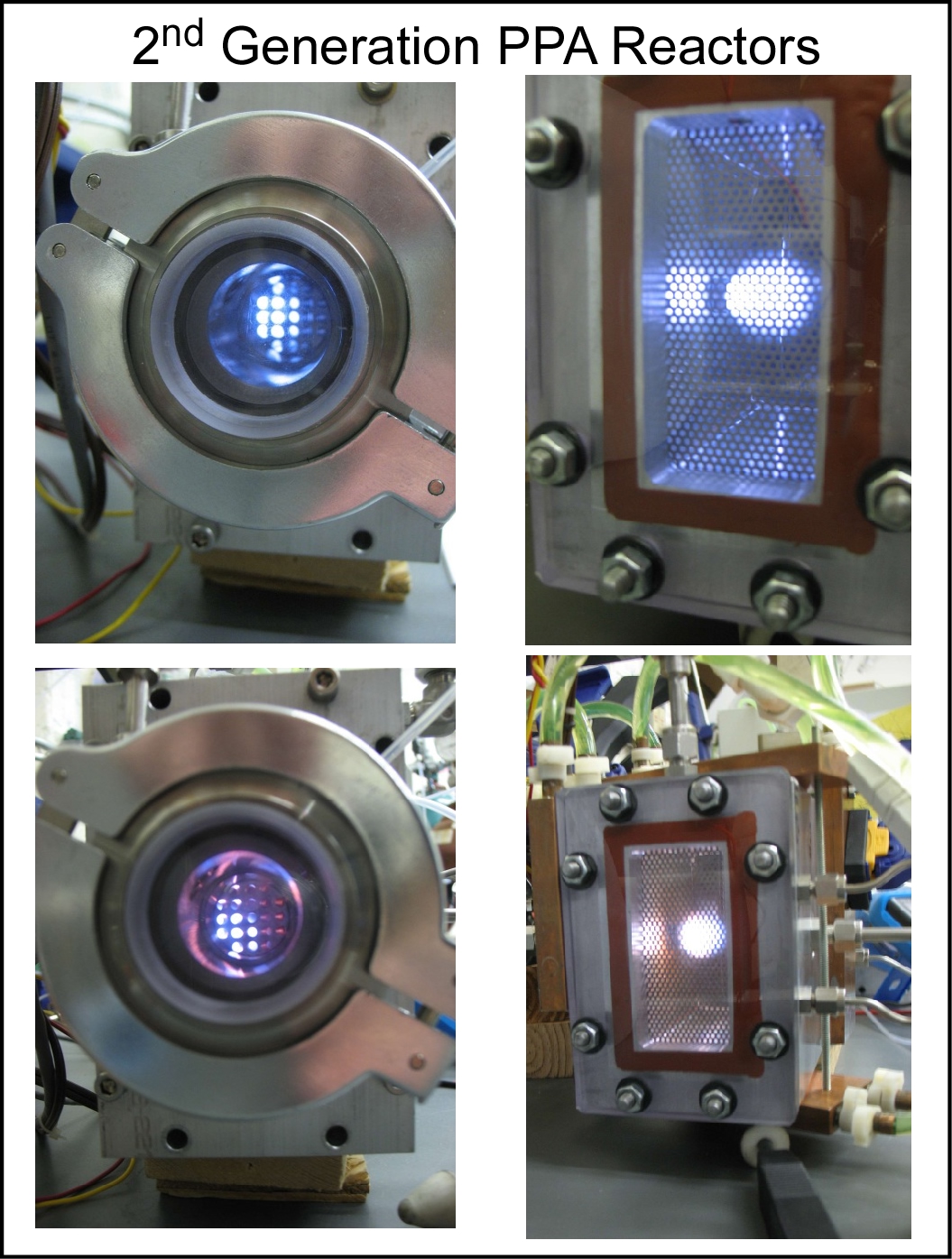

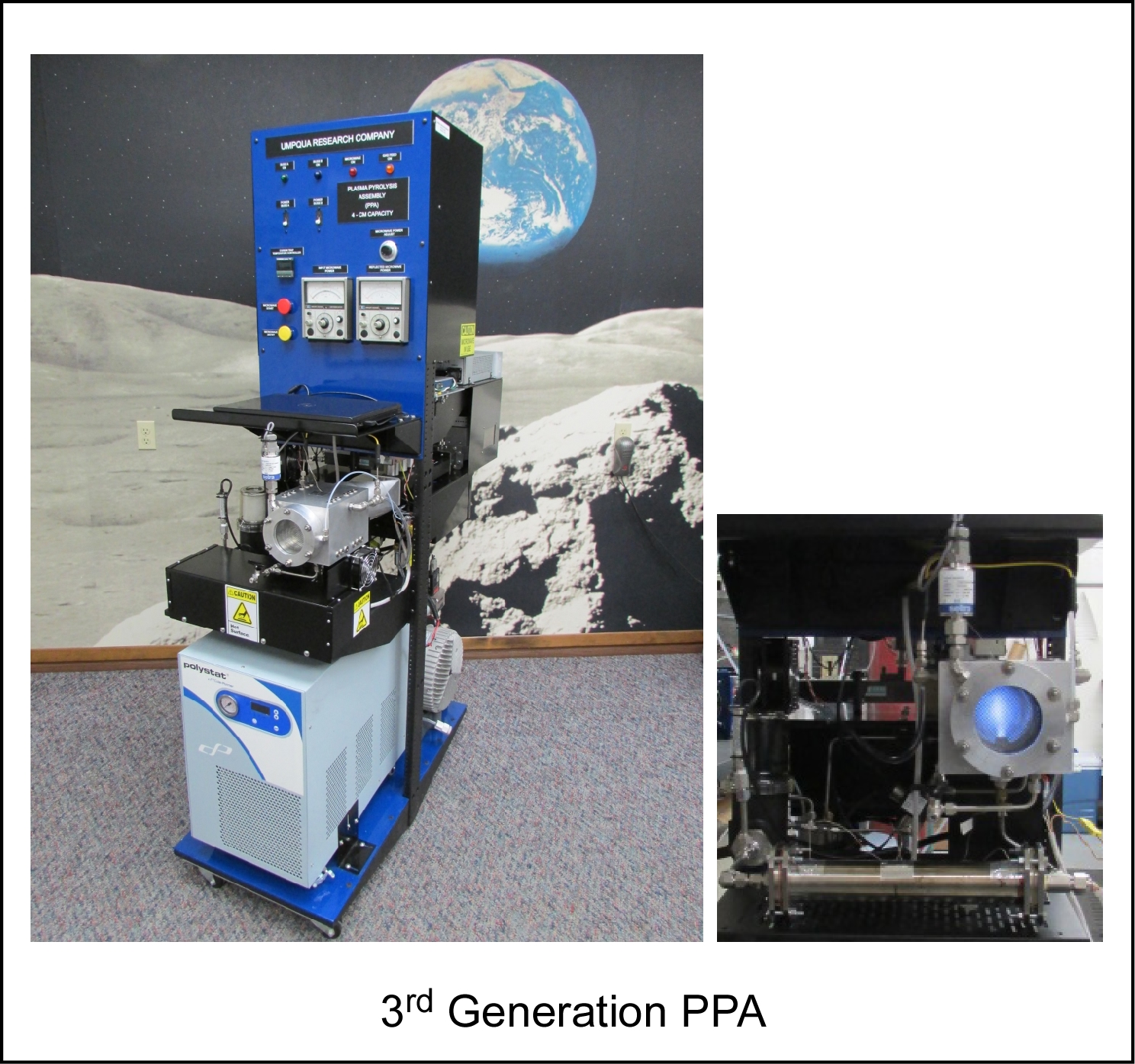

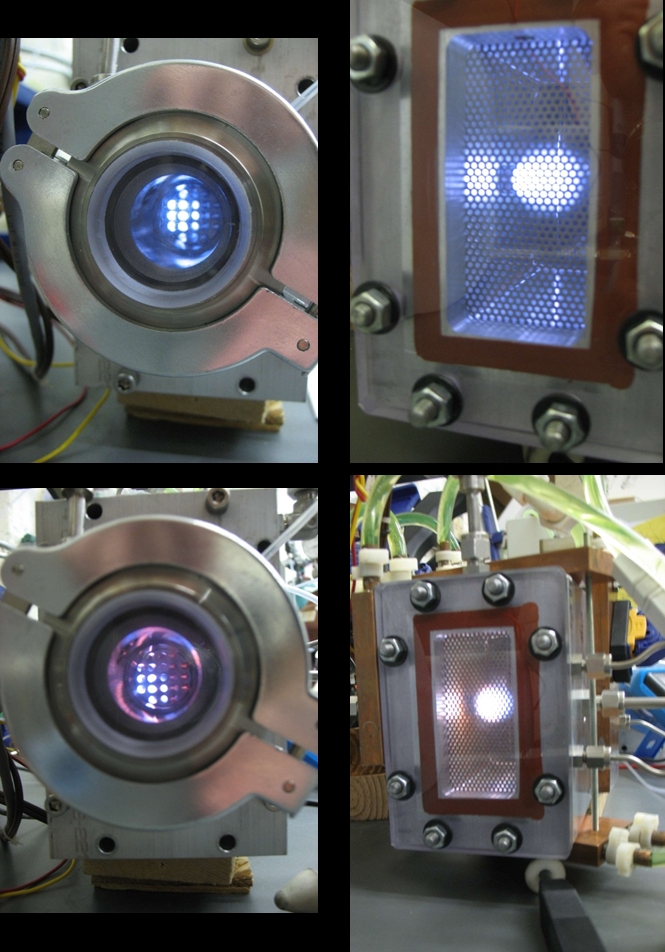

Umpqua Research Company is currently developing two different technologies for recovering O2 from CO2. The first is the Plasma Pyrolysis Assembly (PPA) that closes the resource recovery loop by decomposing methane (CH4) generated from the Sabatier reaction. This allows for recovery of approximately 85% of the hydrogen that is used in the initial reaction with CO2 to produce CH4 and H2O. The second is URC's Bosch reactor. The Bosch reactor is a catalytic reactor that produces carbon and water from the direct reaction of CO2 and H2. This processor permits recovery of nearly 100% of the valuable O2 and H2.

|

|

| PPA Reactor: Second Generation | Bosch Reactor: First Generation |

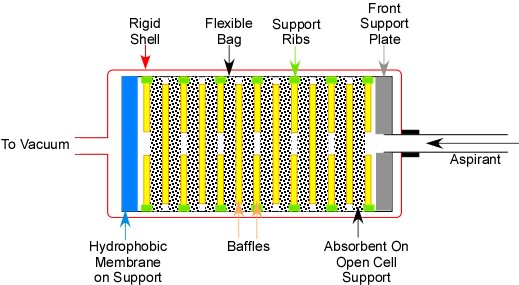

In addition to oxygen recovery, URC has recently applied for patent on a microgravity compatible medical aspiration system for containment of bodily fluids and other hazardous liquids in a microgravity environment. Traditional aspiration devices use buoyancy to close off suction when the collection vessel is full. This prevents distribution of contaminated air into the vacuum source and surrounding environment. URC's microgravity compatible system functions regardless of orientation, which enables quick and reliable collection of these contaminants in a space habitation. We are also marketing the cartridges for use in unstable environments on Earth. Emergency medical care on uneven terrain, remote rescue situations, shipboard in rough seas, and within other highly mobile rescue platforms are all potential applications where an orientation independent system can enhance medical care.

Medical Grade Suction Device